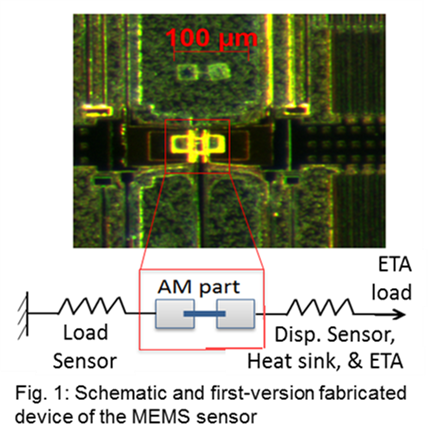

New polymer-based additive manufacturing (AM) systems have recently been developed that use 2-photon lithography to write 3-dimensional features with a resolution of approximately 200 nm. However, little is known about how processing parameters or the uncured polymer formulation effect the mechanical properties of the printed nanoscale structures. Therefore, we have developed a MEMS-based mechanical testing system onto which nano-AM structures can be printed in order to directly measure the mechanical properties of the 3D printed polymer structures. In this system, the nano-AM specimen is printed so that it is suspended between two MEMS stages. Each MEMS stage is connected to a set of capacitive sensors in order to be able to measure the displacement of each stage during testing. A thermal actuator is used to pull on one of the stages and to apply strain to the printed polymer sample. A capacitive sensor attached to the second stage is used to measure the total force applied to the sample. For precise and accurate characterization of a variety of print parameters, two different tensile testers have been created, one with a fine displacement resolution of 0.25 nm and the other with a high load capacity of 25 mN. Thus, this tensile tester can be used to generate the force-displacement curves for a wide verity of printed features, thereby enabling the characterization of the mechanical properties of nano-AM structures with unprecedented precision. This is a critical advance in our ability to relate the mechanical properties nano-AM materials to their printing processing parameters which is a critical first step towards optimization the printing process.