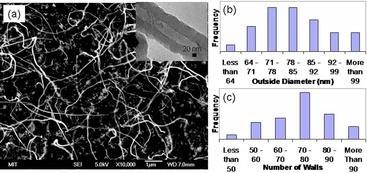

In this project a growth model was developed to control the diameter and number of walls in multi-walled carbon nanotubes grown by chemical vapor deposition (CVD). From this model, tunable process parameters may be used to control the geometry or stiffness of multi-walled carbon nanotubes (MWCNTs). This is important to devices that rely on the compliance of MWCNTs in order to achieve specific performance requirements, e.g. deflection or stiffness. Examples of these types of devices include relays, resonators and flexural bearings for small-scale actuators. It is necessary to control the stiffness of these mechanisms because the force, stroke, and device bandwidth depend upon the stiffness of the constituent MWCNTs. For a given length MWCNT, the stiffness is controlled by the MWCNT diameter and the number of walls in the MWCNT. The diameter and number of walls are controlled by adjusting several growth parameters – temperature, catalyst film thickness, and hydrocarbon concentration. Using thermodynamic relations, optimal growth parameters can be determined for CNTs with specific stiffnesses and natural frequencies. Overall, I was able to control the CNT geometry with less than 7 percent error and the stiffness and natural frequency with less than 2 percent error.