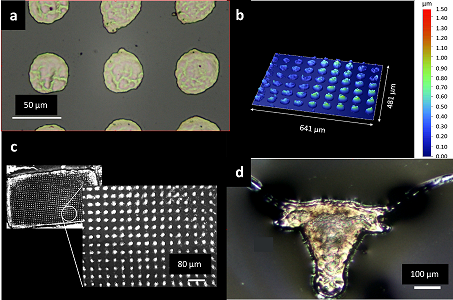

Additive manufacturing is well suited to making complex structures, but unfortunately current commercially available metal additive-manufacturing tools have feature-size resolutions of > 100 μm, which is too large for microelectronic interconnects. Research-grade metal additive manufacturing tools do exist, but their build rates are generally too slow for commercial applications. Therefore, the goal of the additive manufacturing work at the NDML is to improve the minimum feature-size resolution of metal additively-manufactured parts by up to two orders-of-magnitude, while still maintaining the throughput of traditional additive manufacturing processes. In order to achieve this goal, the NDML has developed a new microscale selective laser sintering system (μ-SLS) that uses micromirrors, high-speed nanopositioning stages, and a complex optical design to achieve write speeds on the order of 300 mm/s, and a feature-size resolution of ~ 1 μm. In this system, a laser is coupled to a fiber optic lens and directed off a micro-mirror array through a set of focusing objectives. This allows each 7.6 μm by 7.6 μm pixel in the micromirror array to be focused down to a spot size of approximately 1 μm. The μ-SLS also replaces the microscale powders used in conventional SLS processes with a nanoparticle (NP) ink. The use of NP ink in the μ-SLS system is required to build layers that are approximately 1 μm thick, because it is necessary to use particles that are at least one order-of-magnitude smaller than the desired layer thickness. The use of the NP ink also helps to prevent agglomeration of the nanoparticles during the powder-spreading process. To precisely spread the NP layers during the build process, a nanopositioning system with a resolution of better than 10 nm is integrated with a slot-die coating system. Finally, the system also uses a heated substrate coupled with a precisely controlled laser input to achieve better control over the heat-affected zones around the μ-SLS part and to improve the resolution of the system. Through the use of these combined innovations, the lab has developed a μ-SLS system capable of build rates of approximately 1 cm3/hr while achieving a feature-size resolution of ~ 1 μm. The figure above shows single layer sintering results with Silver NP ink. a) Array of 40 μm diameter circles with 80 μm pitch b) Surface topography of an array of 40 μm diameter circles with 80 μm pitch. c) 2.3 mm by 1.2 mm array sintered on a 1 μm thick Ag NP ink layer. (inset) Enlarged image of an array of 20 μm diameter circles with 40 μm pitch. d) Longhorn logo with smallest feature size around 7 μm near the tip of the longhorn ears