The development of micro and nanoscale additive manufacturing methods in metals and ceramics is important for many applications in the aerospace, medical device, and electronics industries. For example, if we can fabricate additively manufactured parts with micron-scale resolutions, it becomes possible to produce materials with controlled microstructures. Such materials can exhibit very high strength-to-weight ratios, which is critical for a number of applications in the aerospace industry. Similarly, the medical industry could benefit from the additive manufacturing of metal parts with controlled microstructures since this process could be used to fabricate custom implants with enhanced surface structures to either promote or prevent the adhesion of cells to the implant in specific areas. Unfortunately, most commercially available metal additive manufacturing tools have feature-size resolutions of greater than 100 μm, which is too large to precisely control the microstructure of the parts they produce. A few research-grade metal additive manufacturing tools do exist, but their build rate is generally too slow for commercial applications. Therefore, the goal of the additive manufacturing work performed in the NDML at UT-Austin is to improve the minimum feature-size resolution of metal additively manufactured parts by up to two orders of magnitude, while still maintaining the throughput of traditional additive manufacturing processes.

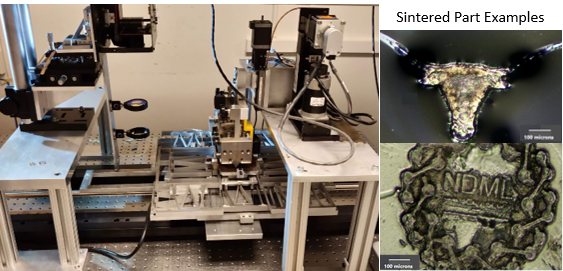

Figure: μ-SLS system showing the optical/coating sub-systems along with the liner servomotor and air bearings used to transport the build substrate between the two sub-systems. An XY nanopositioning system with interferometric feedback sensors is used to precisely and repeatably position the build substrate under the optical sub-system for high speed patterning of each layer in the build process