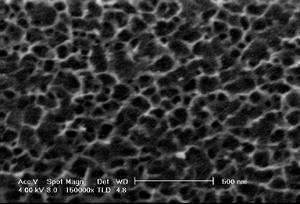

The excellent electrical and mechanical properties of porous nanostructured titania (NST) make it an ideal material for many different applications including dye sensitized solar cells (DSSC). While DSSCs are cheaper to manufacture than silicon-based cells, they are also less efficient. The efficiency of the DSSCs depends on how well the sensitizing dye coats the cell and how well the electron recombination source infiltrates into the porous NST. Consequently, the structure of the NST has a great effect on the efficiency of the cell. Different processing parameters were studied to determine their effects on pore size and surface area. Overall, it was found that increasing the deposition rate and the thickness of the original titanium film increased the pore size of the NST. Also, it was found that increasing the concentration of the hydrogen peroxide used to oxidize the titanium, increased the pore size of the NST. In general, it was also found that as pore size increased, surface area decreased.