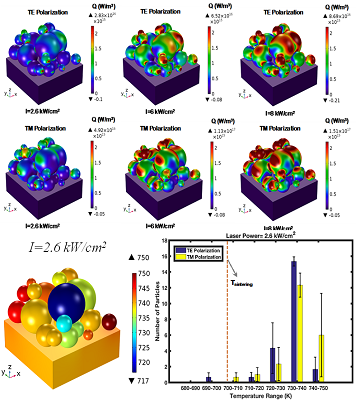

In addition to the experimental μ-SLS testbed itself, we have developed new NP-scale models of the μ-SLS build process. Modeling the μ-SLS process is challenging because most macroscale models of the SLS process rely on assumptions that are no longer valid when the size of the particles involved is smaller than the wavelength of the laser being used to sinter them. In modeling the μ-SLS process we must account both for the wave nature of light and the fact that the heat transfer in the μ-SLS process is dominated by particle-to-particle contact resistances, which change significantly as the NPs start to sinter together. Finally, the agglomeration of nano-particles in the powder bed must be accurately modeled in order to precisely predict the formation of defects in the final parts produced. The discrete element simulations coupled with finite element heat transfer models of the laser interaction with the NPs are used to determine how heat is generated within the NP bed and how that heat causes a rise in the bed temperature. Phase-field modelling is then used to predict how the nanoparticles in the μ-SLS powder bed will fuse together during the sintering operation. This modeling involves simulations of the laser-nanoparticle interactions, heat transfer within the powder bed, and nanoparticle sintering, to predict final part formation. The goal of this modeling effort is to be able to predict the quality of a part produced using any given processing conditions, in order to produce parts that are “born certified”.