Through the application of compact, MEMS-based single chip atomic force microscopes (sc-AFMs) with high scanning speeds, we have developed a R2R metrology tool that greatly increases the throughput and modularity of direct, nanometer-scale measurement on flexible substrates. Designed to provide feedback for a R2R nanopatterning applications, the proof-of-concept system consists of a simple three roller unwind-idler-rewind web-handling arrangement, with the idler roller supported by radial air bearings to enable sensitive, on-roller measurements of the polycarbonate web. Two voice-coil driven vertical, double parallelogram flexure mechanisms are used to precisely position a gantry that holds the sc-AFM probe over the idler roller for web inspection. The nanopositioning sub-system quickly brings the sc-AFM probe within its 20 µm scanning height envelope on startup and rejects any external disturbances that could cause destructive tip-web contact. The probe is held at ideal scanning height for in-line measurement by compensating for idler roller eccentricity and topology using an offline map. Overall, this R2R nanometrology concept is highly scalable due to the modular nature of the fine-approach mechanism, sc-AFM sub-system, and parallelized, discrete control of each individual sc-AFM. We have also recently demonstrated that this system is capable of achieving sub-1 nm vertical resolution, 16.6 nm lateral resolution, and a throughput of 400 μm2/min with a web speed up to 2 m/min., making it suitable for a large variety R2R nanometrology applications.

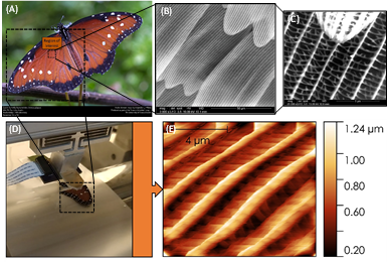

Figure: (A) Queen Butterfly (B) and (C) SEM images of hierarchical wing microstructure (D) In-line sc-AFM scan of butterfly wing on polycarbonate showing the ability of the system to measure (E) complex nanoscale structures